Additive manufacturing is defined as the process of shaping a part by adding material, by stacking successive layers, as opposed to material removal processes such as machining. Additive manufacturing is mostly computer-aided. The term is synonymous with three-dimensional printing or 3D printing, which are consumer names. Additive manufacturing is a terminology used in the industrial world. (3D printing).

History of Additive Manufacturing

Charles Hull in 1984 gave birth to stereolithography. At the same time other technologies will start to see the light of day! 1984 is also the year when the FDM process was developed. Then MIT invented the multicolor binder-jet process.

Powder sintering processes develop in the 90’s, during this time the first major productions reinforce the growing interest in additive manufacturing! With for example the first prosthesis implanted on humans in 1999.

A revolution in 3D printing

Often presented as the new industrial revolution, the additive manufacturing process opens the doors of the future. Indeed, 3d printing combines speed of execution, economy of materials, complexity of models, resistance and quality while freeing itself from a large number of technical constraints. This makes it possible to democratize its use

Additive manufacturing, the functioning

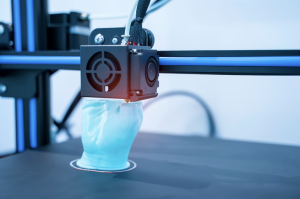

It starts with the virtual realization of a 3d part using a computer tool. This part is then cut virtually into slices by the software, which sends the information layer after layer to a metallic 3d dot printer. 3d printing gives a material reality to the digital. It is a transcription of the digital into the physical, and rather than removing material as in traditional manufacturing and machining processes, 3d printers add more. This is how we move from a subtractive to an additive manufacturing process

This opens up many creative possibilities. How does it work in practice?

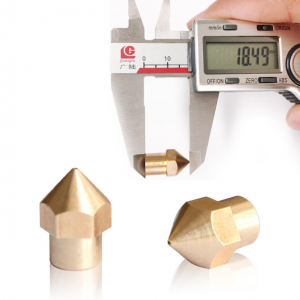

The metal powders are injected into the machine nozzle to form a homogeneous jet. As the powders pass through the nozzle, they are melted, resulting in a homogenous, dancing metallic deposit with material characteristics that lie between those of castings and those of forged parts. The deposited material is locally protected from oxidation by a neutral gas. The printer then stacks layer after layer this metallic deposit to create, repair or add functionalities to an existing part from a digital file.

The fields of application

Additive manufacturing (initially called “rapid prototyping”) now makes it possible to manufacture functional parts in multiple fields:

- Medical field: Resin, plastic or metal are used to make many prostheses with additive manufacturing.

- Aeronautics: Additive manufacturing is used to produce many complex geometrical parts in aeronautics.

Thank you for reading our article! If you are a company that can benefit from the use of 3D printing, contact us to benefit from the advice of our experts!

To learn more about 3D printing, visit the blog of TH Industries, 3D printing expert in Angers.

Laissez nous votre commentaire

Merci pour votre visite

Notre mission… vous proposer la conception réalisation de pièces techniques résistantes et fonctionnelles en impression 3D.

Continuez la lecture...

Suivez-nous sur Facebook

Découvrez nos vidéos

Vous souhaitez produire des petites ou des grandes pièces ? Unitaires, prototypes ou en série ?

Parlez-nous de votre projet!

Demandez une consultation téléphonique

au 06 95 87 61 58